Self-Priming

Diesel/Gasoline/Electric

Booster

Dredge

Submersible

Dewatering

Submersible Turbine

Axial Flow

High Chrome/Abrasion Resistant

Construction

PUMPS

PUMPS

Learn more about our pumps below.

Aaron Hollis

(Project/Safety Director)

(678) 378-8919

Contact Us Today!

Clay Hollis

(Owner)

(678) 850-6031

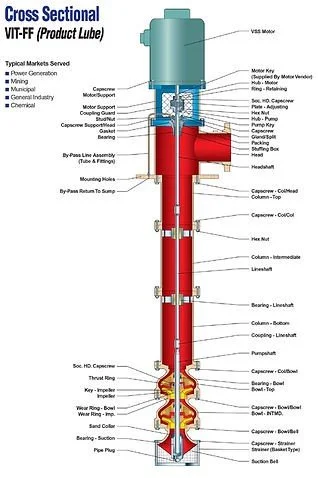

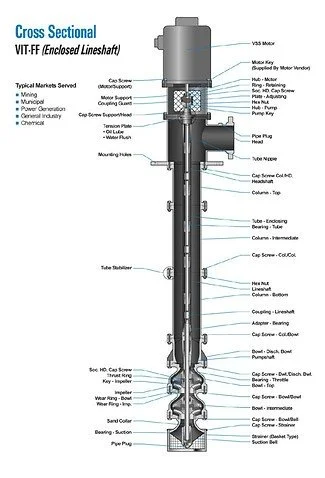

Turbine Pumps

Advantages

Highest efficiency: This results in lower energy usage, superior performance, and lower ownership costs

Lowest capital cost: This equates to lower total ownership costs.

Lowest repair costs: Same evaluation.

Longer wear life: Some pumps have recorded 15-25 years of life with moderate preventive maintenance.

Disadvantages

Not well suited to handle abrasive solids.

Semi-skilled labor is recommended for repairs, such as rock services.

Turbine Pump Data (PDF)

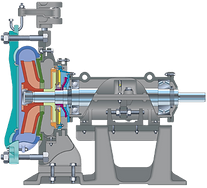

Slurry Pumps

Cornell's SP Series Slurry pump is equipped with patented Cycloseal® technology that caters to the Crushed Stone Industry. It offers a diverse range of mine dewatering pumps and serves as an ideal solution for abrasive applications throughout the mill process. The SP Series Slurry pump is available in both rubber and metal-lined configurations to handle different particle sizes and pH requirements. Thanks to Cycloseal® technology, the pump can run dry for an indefinite period. Can your slurry pump do that? The strictest standards are maintained in the manufacturing of Cornell's slurry pumps for coarse abrasives, making them ideal for the Crushed Stone Industry.

This slurry pump is unique in the sense that it can operate continuously without any damage and has a lifespan that is three to four times longer than its competitors. Unlike other pumps, it doesn't require a water supply line to the stuffing box, which means you don't have to worry about leaks or wear costs. This pump is built to last and can run for a long time, giving outstanding performance.

Model K

Model K Pro

Model HD

The pump uses a metal impeller as standard.

The design can also accommodate a molded rubber impeller in the future.

The casing is made of strong spheroidal graphite iron, while the suction inlet and casing are lined with natural rubber.

The impeller and other wet-end components are made of highly abrasion-resistant high-chrome white iron, with a Brinell hardness of 680 to 720.

The high-chrome impeller can withstand "tramp" metals and achieve higher tip speeds.

The radial impeller vanes can clear solids and reduce pressure at the suction-side clearance, which reduces solids grinding and recirculation.

The tight back liner clearance maximizes packing and shaft sleeve life. Usually, this clearance is opened up as the impeller wears and needs adjusting.

The reverse taper roller bearings purge grease to the outside to prevent the ingress of slurry and over-greasing of the bearing cartridge.

The tight clearance between the wear ring and impeller reduces suction-side slurry recirculation by up to 95%.

Pumps feature a patented, adjustable suction-side sealing system that includes a wear ring that runs against the machined face of the impeller near the eye.

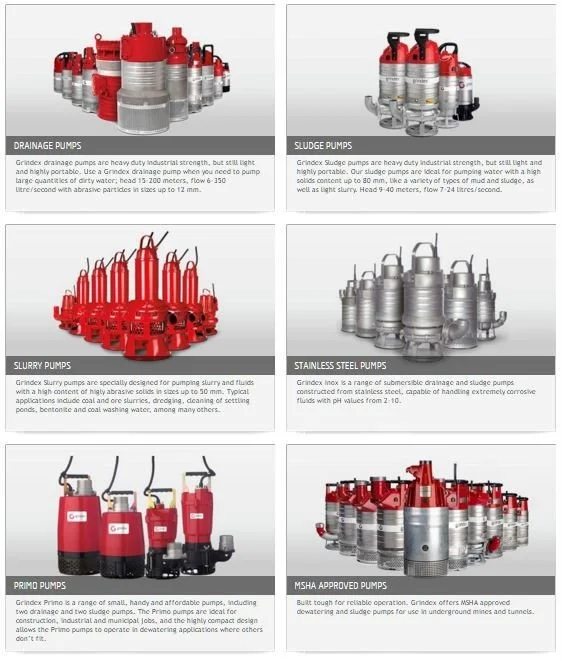

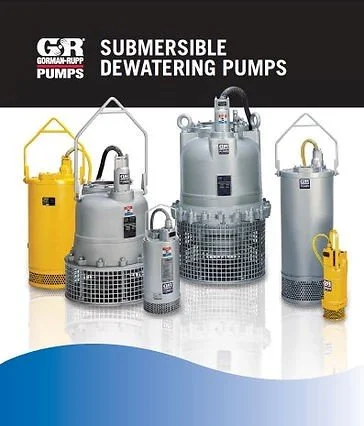

Submersible Pumps

Our company offers one of the largest submersible pumps in the industry today, boasting a capacity of 2,500 gallons per minute and 275 horsepower. This pump is capable of reaching a total dynamic head of 600 feet, making it an exceptional solution for businesses with high-volume pumping needs. Our submersible pumps are engineered to be both reliable and efficient, and we are confident that they will meet the requirements of our clients. Please do not hesitate to contact us for further information or to place an order.

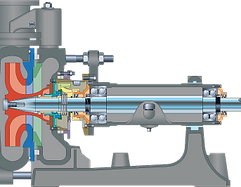

End Suction Centrifugal Pumps

Portable Pumps

Experience the convenience of our portable pumps, available in three different power options - diesel, gasoline, and electric. Whether you need to pump water, fuel, or other fluids, our pumps are built to deliver reliable and efficient performance. Choose the power source that best meets your needs and take advantage of the portability and versatility that our pumps offer.